Call us: +86 13554937406

Fiber optic networks demand precision for reliable performance. Curious about the role of a fiber cleaver in these setups? A fiber cleaver ensures optical fibers have perfectly flat surfaces for splicing, critical for minimal signal loss and efficient data transmission in fiber optic systems. Precision cutting is vital in fiber optic installations. Using a quality cleaver guarantees top-notch connections, vital for rapid data transfer. As a professional, I’ve often stressed how this tool’s precision can impact overall network quality. Let’s explore the nuances of fiber-cleaving tools.

What Is a Fiber Cutter?

Navigating the toolbox for fiber optics can be puzzling. Do you wonder how a fiber cutter differentiates itself? A fiber cutter makes rough cuts to prepare optical fibers for precise cleaving, easing subsequent precision tasks in fiber installations. ! Fiber cutters handle initial cuts on optical fibers. Unlike cleavers, they’re designed for durability rather than precision. This rough cut prepares the fiber length for further processing. The cutter’s role in mitigating damage ensures smoother cleaving. These preparatory steps, though simple, avoid complications during precision splicing, a critical factor for long-distance connections. It’s essential to choose the right tool combination to ensure seamless assembly and optimal performance, particularly when operating under tight deadlines or in challenging environments where fiber integrity is non-negotiable.

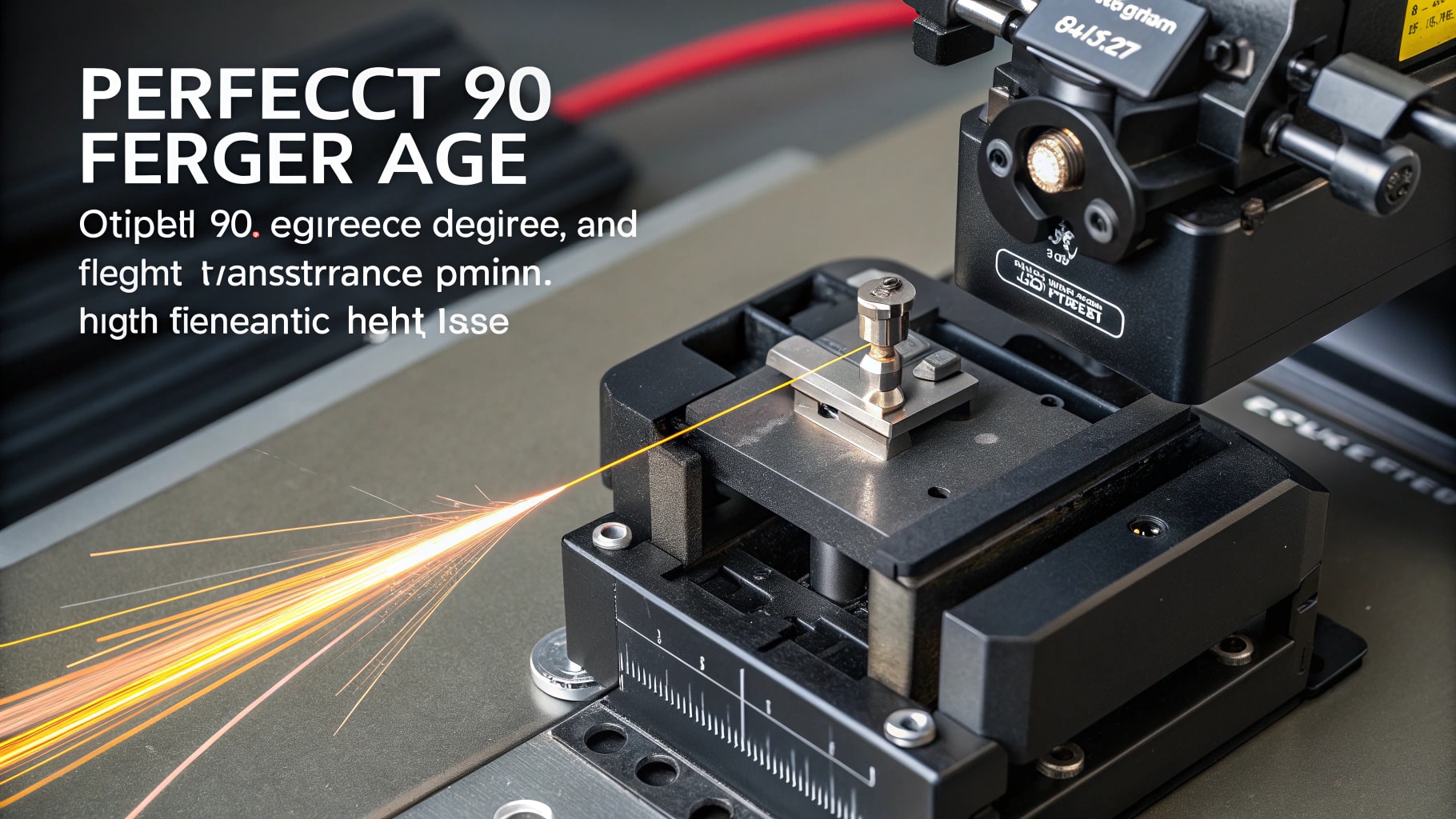

At What Angle Does the Cleaver Cut the Fiber?

Correct cutting angles ensure optimal fiber performance. Ever questioned the precision of these angles? A fiber cleaver typically cuts at a 90-degree angle, essential for accurate fiber alignment and robust data transmission in fiber optic networks.

The integrity of a fiber optic connection heavily depends on cutting angles. A 90-degree cleave offers optimal alignment, ensuring minute signal loss and high transmission clarity. Deviation increases splice loss. This precision is achieved by tension-adjusted blades, which maintain consistent accuracy. Consistency in cutting reduces maintenance needs, crucial for remote deployments. My experiences have shown that rigorous adherence to this angle maximizes system reliability, vital for high-stake projects where failure is not an option.

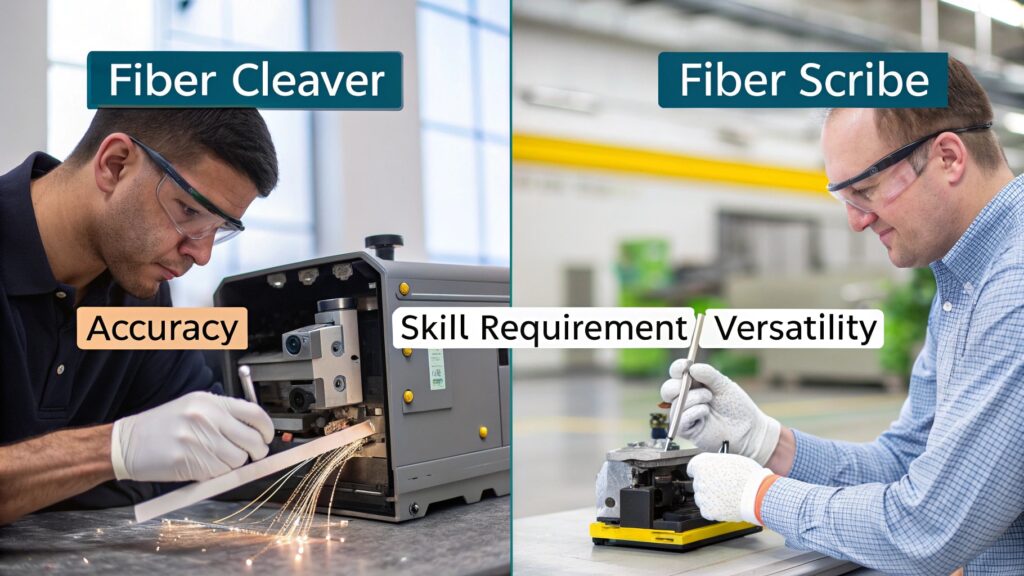

What Is an Alternative to a Fiber Cleaver?

Versatility in tools is crucial for adaptability. Ever thought about alternatives to the fiber cleaver? Fiber scribes serve as alternatives, manually scoring and breaking fibers, though requiring more skill for consistent precision compared to automated cleavers.

Fiber scribes offer a manual way to prepare fibers for splicing. They involve scoring the fiber surface before applying pressure to break it. Skilled hands can achieve similar precision as automated cleavers, though the risk of uneven breaks is higher. This option can be budget-friendly and suitable for smaller projects. However, the potential for error makes routine quality checks necessary. Experience dictates that in high-volume tasks, time-consuming manual processes can accumulate significant downtime, which is why an automated cleaver is often preferred in professional settings.

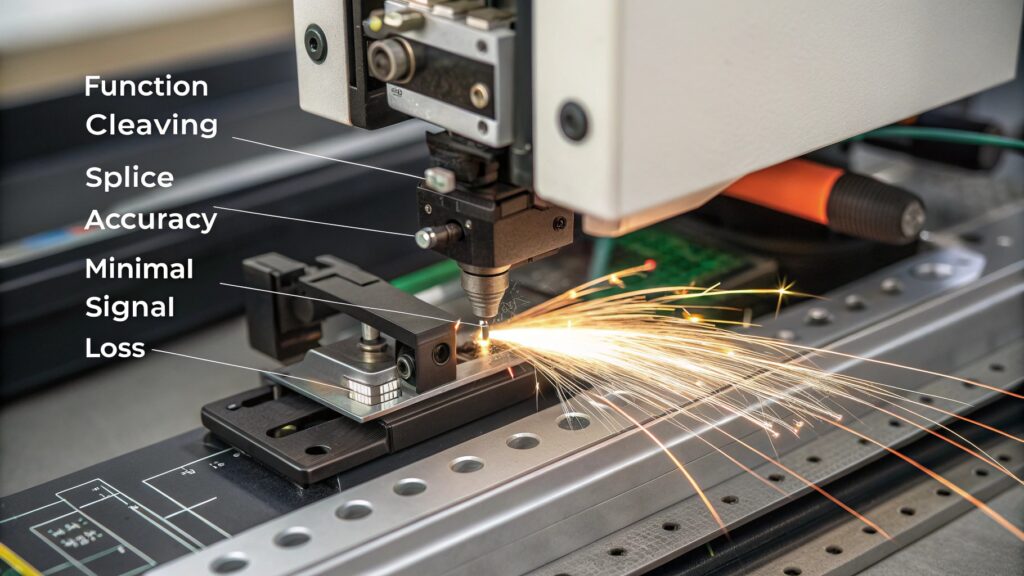

What Is the Function of a Cleaver?

Understanding tool function can optimize performance. What exactly does a cleaver do in its operation? A fiber cleaver creates perfectly flat end surfaces on optical fibers, crucial for optimal splicing, which in turn minimizes signal loss.

The primary function of a cleaver is producing flat end surfaces, essential for splicing accuracy. A consistent cleave reduces splice loss, enhancing data transmission efficiency. Automation in modern cleavers ensures less room for error, promoting consistency. In my early days, mastering the cleaver’s function was challenging but crucial for building reliable networks. The precision achieved by understanding and correctly using a cleaver cannot be overstated in ensuring robust network integrity, particularly when servicing high-demand areas or infrastructures.

Conclusion

Mastering the use of fiber cleavers, cutters, and alternatives ensures precision and reliability in fiber optic networks, vital for optimal connectivity and efficiency.

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.