Call us: +86 13554937406

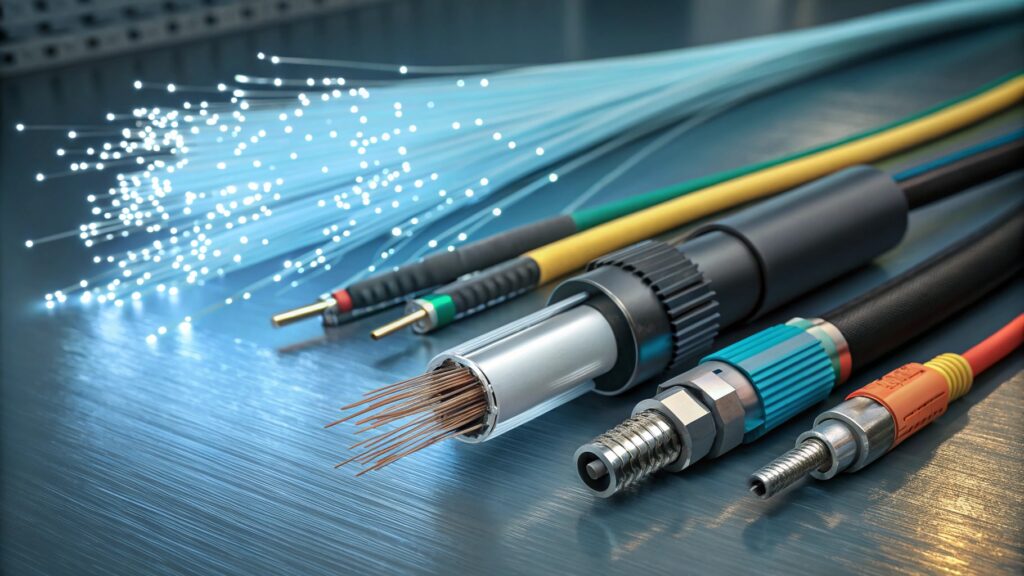

Fiber optics is the backbone of modern communication, but have you ever wondered what makes it work so efficiently? The answer lies in the tools we use. A fiber cleaver is an essential tool for cutting optical fibers with precision. It ensures fibers break cleanly for effective splicing, enhancing signal transmission, and maintaining the network’s quality. Understanding how these tools function offers a glimpse into the world of fiber optics. Let’s explore further to understand their types, uses, and best practices in the industry.

How Does a Fiber Cleaver Work?

Precision in telecommunications makes all the difference, and fiber cleavers play a pivotal role. But what’s the secret to their effectiveness? Fiber cleavers conduct clean, precise cuts on optical fibers by applying controlled pressure. This process minimizes signal loss and ensures effective transmission over networks, making every slice critical! A fiber cleaver’s operation begins with careful alignment of the fiber, followed by scoring with an automatic needle. By focusing on precision, the cleaver ensures minimal angle error and cleanliness for fusion splicing, crucial for efficient data transmission. Without precise cleavers, splices would be inefficient, leading to data loss. Such accuracy underpins the reliability of global communications networks, making fiber cleavers indispensable in the industry.

What Types of Fiber Cleavers are Available?

Selecting the right tool in a market overflowing with options can be daunting. What about fiber cleavers—how do you know which one suits your needs? Fiber cleavers come in several types: single fiber, multi-fiber, and automatic. Each type is designed for specific applications, tailored to different operational needs within the fiber optic industry.

To choose the ideal fiber cleaver, consider your project’s scope and complexity. Single-fiber cleavers are perfect for precise, individual cuts, most effective in detailed projects. Multi-fiber cleavers accommodate larger tasks, allowing for quick, efficient cleaving of multiple fibers simultaneously. Automatic cleavers, on the other hand, help reduce human error with automated controls. The right choice ensures job efficiency, improves productivity, and maintains consistent quality in fiber optic work.

What Are the Best Practices for Using Fiber Cleavers?

Technology is advancing, and keeping up with best practices is crucial. How can one use fiber cleavers efficiently and securely? Adopting best practices with fiber cleavers involves regular maintenance, proper handling, and using the right cleaver for each task. These practices ensure reliability and longevity, enhancing network performance.

Regular inspection and cleaning are vital to maintain cutting precision. Replace blades periodically for consistent results. During usage, ensure the work environment is clean and fibers are aligned properly. Selecting the right type of cleaver for your specific task is essential for success. Following these practices not only extends the cleaver’s lifespan but also guarantees quality results in every cut. Proper use and maintenance of fiber cleavers are pivotal in sustaining outstanding performance in fiber optic work.

Conclusion

Fiber cleavers are indispensable to fiber optic technology. Their precision ensures reliable network performance and excellent connectivity. Understanding their function, types, and best practices is key to harnessing their full potential.