Call us: +86 13554937406

In the ever-evolving world of fiber optics, making the right choices can greatly affect your network’s success. Have you considered which fiber cleaver to use? Choosing the right fiber cleaver for single mode fiber ensures precise cuts, reducing signal loss and reflection in long-distance optical networks, critically enhancing performance. Precision cleaving means you need a high-quality tool. The cleaver’s role is crucial in maintaining low insertion loss and high return loss. Single mode fibers often endure long-distance transmissions. Any imperfection in cleaving can degrade signals drastically. Therefore, key features in your cleaver should include a robust blade for consistent alignment and precision, and auto-tension adjustment for perfect cleaves. Efficient cleaving supports long-term network reliability, crucial for seamless communications and reduced maintenance costs.

What Makes a Fiber Cleaver Ideal for FTTH Installations?

The rise of Fiber-to-the-Home (FTTH) requires specialized tools for efficiency and precision. Do you know what makes a fiber cleaver suitable for these installations? An ideal fiber cleaver for FTTH installations is portable and user-friendly, facilitating accurate splicing in tight spaces while maintaining high precision. ! FTTH installations occur in varied environments, demanding compact and handy tools. A suitable FTTH cleaver offers automatic blade adjustments and easy operation. It might feature pre-programmed settings for different fiber types and sizes, enabling swift installations. Portability is essential, allowing technicians to maneuver comfortably within limited spaces without compromising quality. Training on FTTH-specific tools typically involves simpler learning curves, making them accessible to even those with moderate experience. The right cleaver enhances productivity and ensures lasting network performance, which is essential for successful FTTH implementations.

How Can You Choose the Best Fiber Cleaver for Field Use?

Field conditions are unpredictable and challenging. Have you thought about what to prioritize when selecting a fiber cleaver for such environments? Selecting a fiber cleaver for field use requires emphasis on durability, adaptability, and easy maintenance to ensure consistent performance and minimize downtime.

Field conditions can be tough, with extreme temperatures, dirt, and moisture challenging tools routinely. Therefore, you must focus on the cleaver’s construction and maintainability. Models with rugged casings resist physical damage and contamination. Options for quick-change blades minimize downtime, maintaining efficiency on the job. Multipurpose cleavers that adapt to various cable types can be valuable, offering strong practical utility. Moreover, cleaning mechanisms that simplify upkeep are essential for preserving operational standards. The right cleaver enhances worker safety and efficiency, equipping teams to tackle any field environment efficiently.

Why Is a Clean Fiber Cleave Critical for Network Performance?

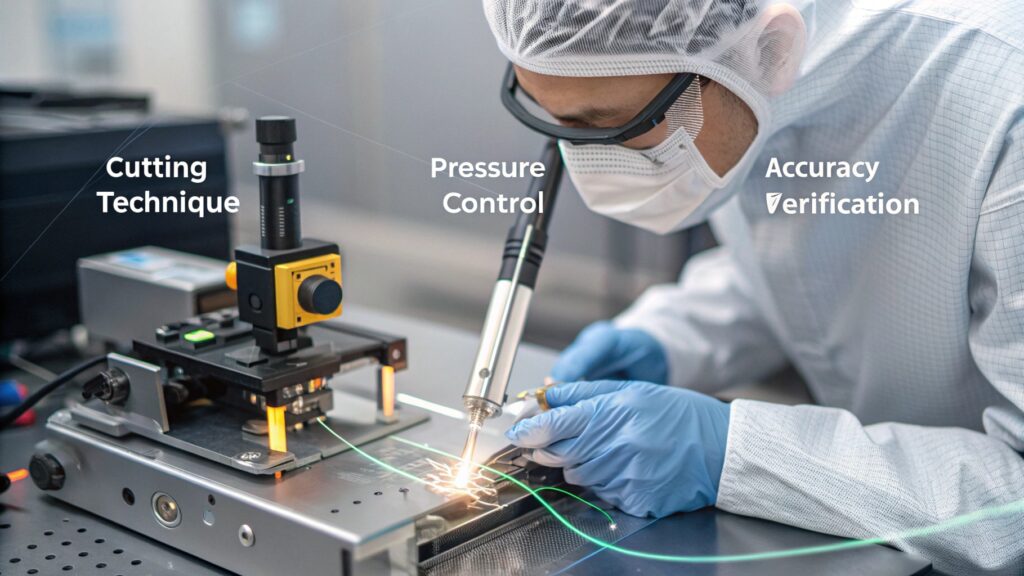

Network efficiency heavily depends on the quality of your fiber cleave. Are you aware of the best practices to ensure cleanliness? Achieving a clean fiber cleave involves meticulous equipment maintenance, precise cutting techniques, and routine accuracy verification to maintain optimal network operations.

A pristine cleave requires consistent blade care and adherence to cutting techniques. Regular blade cleaning should involve alcohol wipes or dedicated kits for effectiveness. Using protective caps can help prolong blade life. Technique-wise, applying consistent pressure ensures accuracy, preventing undue strain on the cleaver. Routine position checks and condition assessments avert dullness, ensuring precision with each cut. Regular accuracy verification using test tools confirms cleave quality. These practices prevent signal disruptions, achieving required efficiency and superior network performance.

Fiber Cleaver vs. Fiber Scribe: Which Is the Right Tool for You?

Choosing between a fiber cleaver and a scribe could affect your project outcomes significantly. Do you know the differences? Fiber cleavers provide precision for critical splicing, while fiber scribes support less demanding field tasks, with each tool catering to different project needs.

A fiber cleaver is designed for accuracy, delivering reliable cuts necessary for professional splicing operations. It is favored in environments where network reliability is non-negotiable. Conversely, a fiber scribe is suitable for flexibility and cost-effectiveness, handling general tasks like repairs and basic field adjustments. Though not as precise, it excels in versatility. Weighing project goals, performance requirements, and available resources helps determine the ideal tool. Understanding each tool’s advantages leads to optimal decision-making tailored to specific needs.

Conclusion

Selecting the right fiber cleaver affects network quality and efficiency. Whether for high-precision tasks or general fieldwork, knowing your options ensures reliable and smooth operations.que volutpat ac tincidunt vitae semper quis.